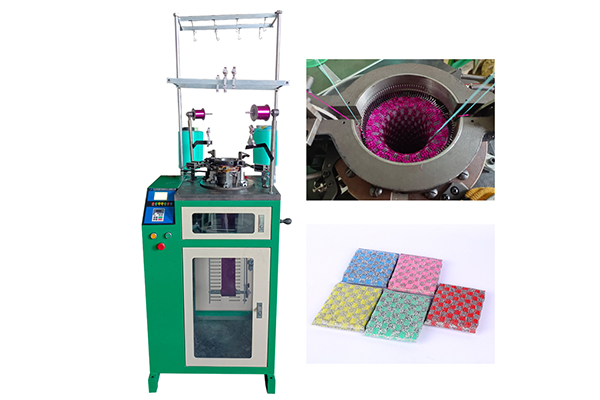

SS Wire Foam Scrubber Machine

The raw materials are polyester DTY 150D and stainless steel wire in diameter 0.09mm.

Regular we have 2 models, one is in 95mm diameter, the other is 102mm diameter, the fabric width can be 8.5cm, 9cm, 9.5cm, 10cm.

- APPLICATIOINS

- MACHINE SPECS

- CONFIGURATIONS

- SS Wire Foam Scrubber

- SS Wire Foam Jacquard Scrubber

- SS Wire Foam Metallic Scrubber

| Machine Specifications | |

|---|---|

| Cylinder dia. | 3.5 in - 4 in. (95, 102mm) |

| Feed | 1 |

| Needle gauge | 8GG, 9GG, 10GG, customizable |

| Control system | PLC, touch screen, English interface, |

| Wire Flatten device | Standard on all models. |

| Output | 0.55-0.65 kgs / hour |

| Height | 86.61 - 94.49 in. (220-240cm) to top creel stand |

| At Floor | 35.43 in. x 31.50 in. (90cm x 80cm) |

| Weight | 661.49 pounds (300kgs) |

| Horsepower | 0.748 HP (0.55 kw) |

| Drive System | AC Motor Controller with smooth start and stop. |

| Standard Electrics | 220 volts, single or 3 phase, 50/60 hz, If need other operating voltage, please contact us freely. |

| Yarn stop motion | Standard on all models. |

| Fabric Collection | In rolls |

| Machine Speeds | Start, stop and jog with three programmable jog speeds. |

| Auto count sensor | Standard on all models. |

| Lubrication System | auto oil pump |

| HS Code | 844711 |

| Technical Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Cylinder Dia. (mm) | Feeder | Capacity (m/h) | Power (kw) | N.W. (kgs) | G.W. (kgs) | PKG Size (cm) | PKG Vol. (cbm) | |

| QJF-QC-95D | 95 (3.7”) | 1 | 7-10m/h | 0.55 | 250 | 300 | 75x64x150 60x47x116 | 1.047 | |

| QJF-QC-102D | 102 (4”) | 1 | 7-10m/h | 0.55 | 250 | 300 | 75x64x150 60x47x116 | 1.047 | |

Jacquard Foam Scrubber Knitting Machine

Material: metallic yarn + polyester 150D or PP 50D.

- APPLICATIOINS

- MACHINE SPECS

- CONFIGURATIONS

- Jacquard Foam Scrubber

| Machine Specifications | |

|---|---|

| Cylinder dia. | 3.5 in - 4 in. (95, 102mm) |

| Feed | 1, 2 |

| Needle gauge | 8GG, 9GG, 10GG, customizable |

| Control system | computerized, English interface, |

| Wire Flatten device | Standard on all models. |

| Output | 0.6-1.0 kgs / hour |

| Horsepower | 0.748 HP (0.55 kw) |

| Drive System | AC Motor Controller with smooth start and stop. |

| Standard Electrics | 220 volts, single or 3 phase, 50/60 hz, If need other operating voltage, please contact us freely. |

| Yarn stop motion | Standard on all models. |

| Fabric Collection | In rolls |

| Machine Speeds | Start, stop and jog with three programmable jog speeds. |

| Auto count sensor | Standard on all models. |

| Lubrication System | auto oil pump |

| Height | 86.61 - 94.49 in. (220-240cm) to top creel stand |

| At Floor | 35.43 in. x 31.50 in. (90cm x 80cm) |

| Weight | 661.49 pounds (300kgs) |

| HS Code | 844711 |

| Technical Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Cylinder Dia. (mm) | Feeder | Capacity (m/h) | Power (kw) | N.W. (kgs) | G.W. (kgs) | PKG Size (cm) | PKG Vol. (cbm) | |

| QJF-QC-102J | 102 (4”) | 2 | 15-20m/h | 0.55 | 200 | 250 | 68x70x152 | 0.724 | |

Jacquard Cotton Scrubber Knitting Machine

Material is polyester yarn or cotton yarn etc.

- APPLICATIOINS

- MACHINE SPECS

- CONFIGURATIONS

- Jacquard Foam Scrubber

- Jacquard Bath Strap

| Machine Specifications | |

|---|---|

| Cylinder dia. | 3.5 in - 4 in. (95, 102mm) |

| Feed | 1 |

| Needle gauge | 8GG, 9GG, 10GG, customizable |

| Control system | PLC, touch screen, English interface, |

| Wire Flatten device | Standard on all models. |

| Output | 0.55-0.65 kgs / hour |

| Height | 86.61 - 94.49 in. (220-240cm) to top creel stand |

| At Floor | 35.43 in. x 31.50 in. (90cm x 80cm) |

| Weight | 661.49 pounds (300kgs) |

| Horsepower | 0.748 HP (0.55 kw) |

| Drive System | AC Motor Controller with smooth start and stop. |

| Standard Electrics | 220 volts, single or 3 phase, 50/60 hz, If need other operating voltage, please contact us freely. |

| Yarn stop motion | Standard on all models. |

| Fabric Collection | In rolls |

| Machine Speeds | Start, stop and jog with three programmable jog speeds. |

| Auto count sensor | Standard on all models. |

| Lubrication System | auto oil pump |

| HS Code | 844711 |

| Technical Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Cylinder Dia. (mm) | Feeder | Capacity (m/h) | Power (kw) | N.W. (kgs) | G.W. (kgs) | PKG Size (cm) | PKG Vol. (cbm) | |

| QJF-QC-110J/C | 110 (4.3”) | 2 | 6-8 m/h | 0.55 | 200 | 250 | 68x70x152 | 0.724 | |

Honeycomb Kitchen Scrubber knitting machine

This machine can be knit bath strap and kitchen scrubber, just with different raw material.

Material is transparent metallic yarn with polyester yarn or PP yarn.

Running mode: outside running

- APPLICATIOINS

- MACHINE SPECS

- CONFIGURATIONS

- Kitchen Scrubber

| Machine Specifications | |

|---|---|

| Cylinder dia. | 3.5 in - 4 in. (95, 102mm) |

| Feed | 1 |

| Needle gauge | 8GG, 9GG, 10GG, customizable |

| Control system | PLC, touch screen, English interface, |

| Wire Flatten device | Standard on all models. |

| Output | 0.55-0.65 kgs / hour |

| Height | 86.61 - 94.49 in. (220-240cm) to top creel stand |

| At Floor | 35.43 in. x 31.50 in. (90cm x 80cm) |

| Weight | 661.49 pounds (300kgs) |

| Horsepower | 0.748 HP (0.55 kw) |

| Drive System | AC Motor Controller with smooth start and stop. |

| Standard Electrics | 220 volts, single or 3 phase, 50/60 hz, If need other operating voltage, please contact us freely. |

| Yarn stop motion | Standard on all models. |

| Fabric Collection | In rolls |

| Machine Speeds | Start, stop and jog with three programmable jog speeds. |

| Auto count sensor | Standard on all models. |

| Lubrication System | auto oil pump |

| HS Code | 844711 |

| Technical Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Cylinder Dia. (mm) | Feeder | Capacity (m/h) | Power (kw) | N.W. (kgs) | G.W. (kgs) | PKG Size (cm) | PKG Vol. (cbm) | |

| QJF-QC-95H | 95 (3.7”) | 4 | 30-35 m/h | 0.55 | 200 | 250 | 68x70x152 | 0.724 | |

| QJF-QC-102H | 102 (4”) | 4 | 30-35 m/h | 0.55 | 200 | 250 | 68x70x152 | 0.724 | |

Metallic Sponge Scouring Pad Knitting Machine

Material: (Flat) Metallized Yarn + Polyester Yarn 150D.

- APPLICATIOINS

- MACHINE SPECS

- CONFIGURATIONS

- Metallic Kitchen Scrubber

| Machine Specifications | |

|---|---|

| Cylinder dia. | 4 in. (102mm) |

| Feed | 2 |

| Needle gauge | 8GG, 9GG, 10GG, customizable |

| Control system | computerized, English interface, |

| Wire Flatten device | Standard on all models. |

| Output | 0.6-1.0 kgs / hour |

| Horsepower | 0.748 HP (0.55 kw) |

| Drive System | AC Motor Controller with smooth start and stop. |

| Standard Electrics | 220 volts, single or 3 phase, 50/60 hz, If need other operating voltage, please contact us freely. |

| Yarn stop motion | Standard on all models. |

| Fabric Collection | In rolls |

| Machine Speeds | Start, stop and jog with three programmable jog speeds. |

| Auto count sensor | Standard on all models. |

| Lubrication System | auto oil pump |

| Height | 86.61 - 94.49 in. (220-240cm) to top creel stand |

| At Floor | 35.43 in. x 31.50 in. (90cm x 80cm) |

| Weight | 661.49 pounds (300kgs) |

| HS Code | 844711 |

| Technical Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Cylinder Dia. (mm) | Feeder | Capacity (m/h) | Power (kw) | N.W. (kgs) | G.W. (kgs) | PKG Size (cm) | PKG Vol. (cbm) | |

| QJF-QC-102 | 102 (4”) | 2 | 15-20 m/h | 0.55 | 200 | 250 | 68x70x152 | 0.724 | |

Inserting Sponge Machine

This machine can automatically turn fabric to another side and insert sponge into the fabric. It is very useful and can save much labour

The machine uses a stepper motor chain to drive the rack teeth to engage the cloth for rapid transmission, so as to realize the bonding and forming of automatic cloth sponge strips.

It can directly enter the full-automatic ultrasonic scourer sponge welding and cutting machine for linkage operation.

- APPLICATIOINS

- MACHINE SPECS

- CONFIGURATIONS

- Kitchen Scrubber

| Machine Specifications | |

|---|---|

| Control system | frequency conversion and pneumatic control |

| Output | 1000 m/h |

| Power supply | Single phase/ Three phase |

| At Floor | 102 in. x 28 in.x 41 in (260cmx72cmx105cm) |

| Weight | 947 pounds (430kgs) |

| Horsepower | 4 HP (3 kw) |

| HS Code | 842839 |

| Technical Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Output | Power | Voltage | N.W. (kgs) | G.W. (kgs) | PKG Size (cm) | PKG Vol. (cbm) | |

| QX-TM-002 | 350m/h (sponge in) | 3 kw | 380 V | 500 | 600 | 273x82x133 | 2.977 | |

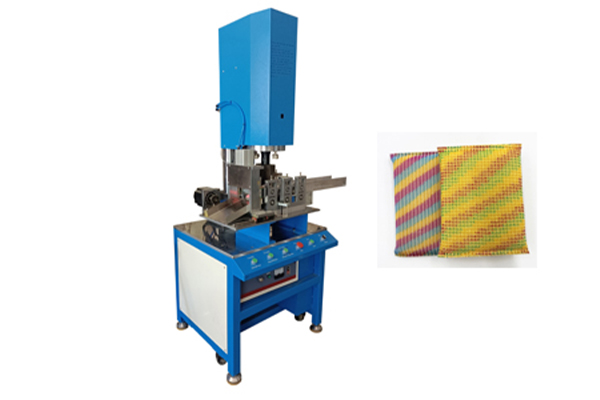

Ultrasonic Foam Scrubber Making Machine

The principle of ultrasonic plastic welding is that a high voltage and high frequency signal (or 15KHz) is generated by a generator, which is converted into high-frequency mechanical vibration through a transduction system and applied to the plastic product workpiece.

The temperature transmitted to the interface is increased through the friction between the workpiece surface and molecules. When the temperature reaches the melting point of the workpiece itself, the interface of the workpiece quickly melts, and then fills the gap between the interfaces. When the vibration stops, the workpiece is cooled and shaped under a certain pressure, and welding is achieved.

The new 15KHz ultrasonic plastic welding machine can weld softer PE and PP materials, as well as large diameter and long length plastic welding parts, to meet the needs of various products. The machines can be operated by one person and packed by only one person, saving labor and producing 30000 pieces per day.

- APPLICATIOINS

- MACHINE SPECS

- CONFIGURATIONS

- Kitchen Scrubber

| Machine Specifications | |

|---|---|

| Voltage | 220V |

| KHZ | 15KHZ / 2600W |

| G.W | 400KG |

| Dimsion | 800x800x1800mm |

| Control Systme | PLC Control System |

| Power Form | Pneumatic |

| Control Method | Automatic |

| Mould Width | 75-125mm |

| Principle of action | plastic / ss wire welding |

| HS Code | 846880 |

| Technical Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Output | Welding Time | Frequency | Power (kw) | N.W. (kgs) | G.W. (kgs) | PKG Size (cm) | PKG Vol. (cbm) | |

| AC420/SS | 35-45pcs/min | 0.01-9.9 | 15 KHZ | 4.2 | 300 | 400 | 98x73x205 | 1.467 | |

| AC420 | 35-45pcs/min | 0.01-9.9 | 15 KHZ | 4.2 | 300 | 400 | 98x73x205 | 1.467 | |